We use CAD software to create designs based on client requirements and select appropriate materials such as stainless steel, aluminum, or carbon steel.

Using laser cutting or water jet cutting technology to ensure smooth, burr-free edges.

Processes like bending and stamping shape the metal sheets into the desired forms.

Precision welding techniques enhance product durability and structural integrity.

Techniques such as powder coating, electroplating, and anodizing improve corrosion resistance and aesthetics.

We use CAD software to create designs based on client requirements and select appropriate materials such as stainless steel, aluminum, or carbon steel.

Using laser cutting or water jet cutting technology to ensure smooth, burr-free edges.

Processes like bending and stamping shape the metal sheets into the desired forms.

Precision welding techniques enhance product durability and structural integrity.

Techniques such as powder coating, electroplating, and anodizing improve corrosion resistance and aesthetics.

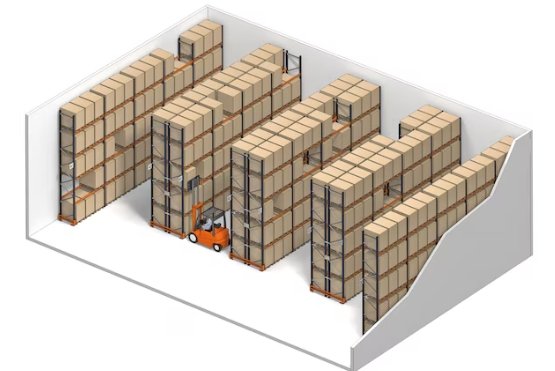

Major advantages of pallet racking

1.Optimisation of loading and unloading times.

2.Compacting of goods and better use of avaliable space.

3.Greater flexibility for their trnasport and handling.

4.Simplicity for stock and inventory control.

5.Reduced handling, transport and storage costs

Major advantages of pallet racking

1.Optimisation of loading and unloading times.

2.Compacting of goods and better use of avaliable space.

3.Greater flexibility for their trnasport and handling.

4.Simplicity for stock and inventory control.

5.Reduced handling, transport and storage costs

Q1: Where can I get product & price information?

A: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: How long can I get the sample?

A: Depends on your specific items, within 3 – 7 days is required generally.

Q3: What’s kinds of information you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better you can provide in STEP or IGS

Q4: what’s the payment terms?

A: We accept 50% as payment deposit when the goods are done, we take photos for your check and you then pay the balance.

Q5: How to deliver the Samples?

A: We will deliver samples through international freight forwarders such as DHL UPS or federal.

Q6: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts

with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q7: Can we get some samples before mass production?

A: Absolutely

Q8: Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q9: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.